A quick Christmas project. I saw this on Vectric’s website, and sadly like so many of their projects, the files were for Aspire owners only. However, they did provide the “cute reindeer” stl file which they got from another source. The files can be found here: V&Co - Vectric Customer Portal

- Machine Type:

- Other Machine

- Software:

- Fusion 360 and Vectric's Vcarve

- Electronics:

- Other Controller

- Machine Time:

- 2.5 hours estimate

- Bit or Laser Size:

- multiple

- Feeds & Speeds:

- 3D carving: 3000mm/min

V-carving and profile cutting: 2500mm/min

- Materials:

- Oak and acrylic paints

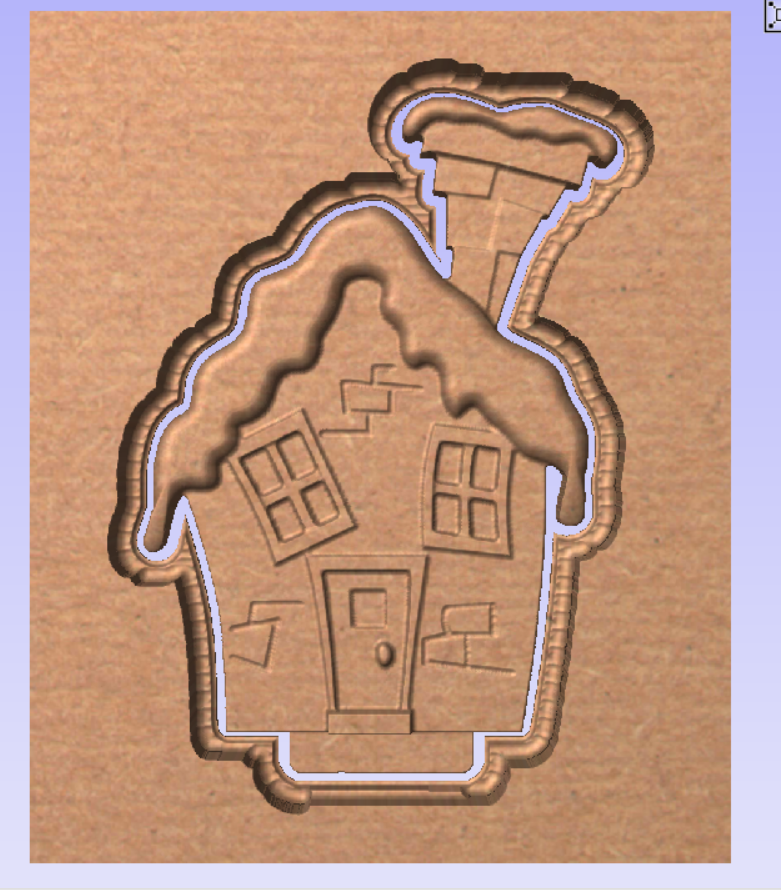

I liked the project and had some old oak pieces that needed to be used. But alas, Vectric did not provide the .stl for the house. So, doing what was done in the video, I created my own house that is similar to the house in the Aspire file. I drew it up in Fusion 360. I added bases that are ¼” thick to both models to fit into the slots on the base piece.

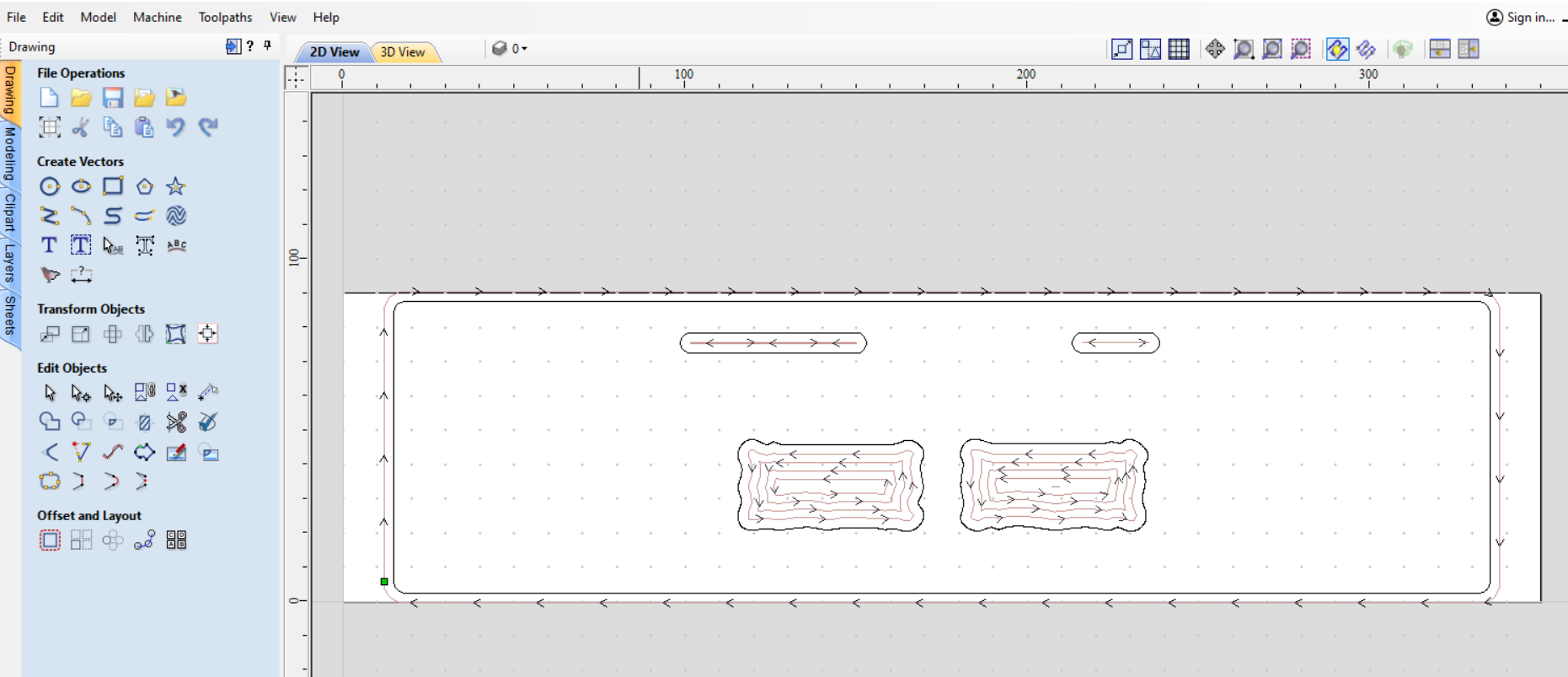

I found that the 3D carved objects should be cut before the base. The reason I found that the 3D objects should be cut first is because it allows for adjustment of the slots on the base to be the right length/width so the fit is tight. I actually carved a couple versions of just the slots in scrap to be sure everything would be a tight fit. My slots for the carved objects are 12mm deep. I also drew the base up in Fusion360, because I find simple 2D dxf files are easier for me since I have been using it for a lot longer. I used Vcarve to generate the tool paths from my Fusion 360 dxf file.

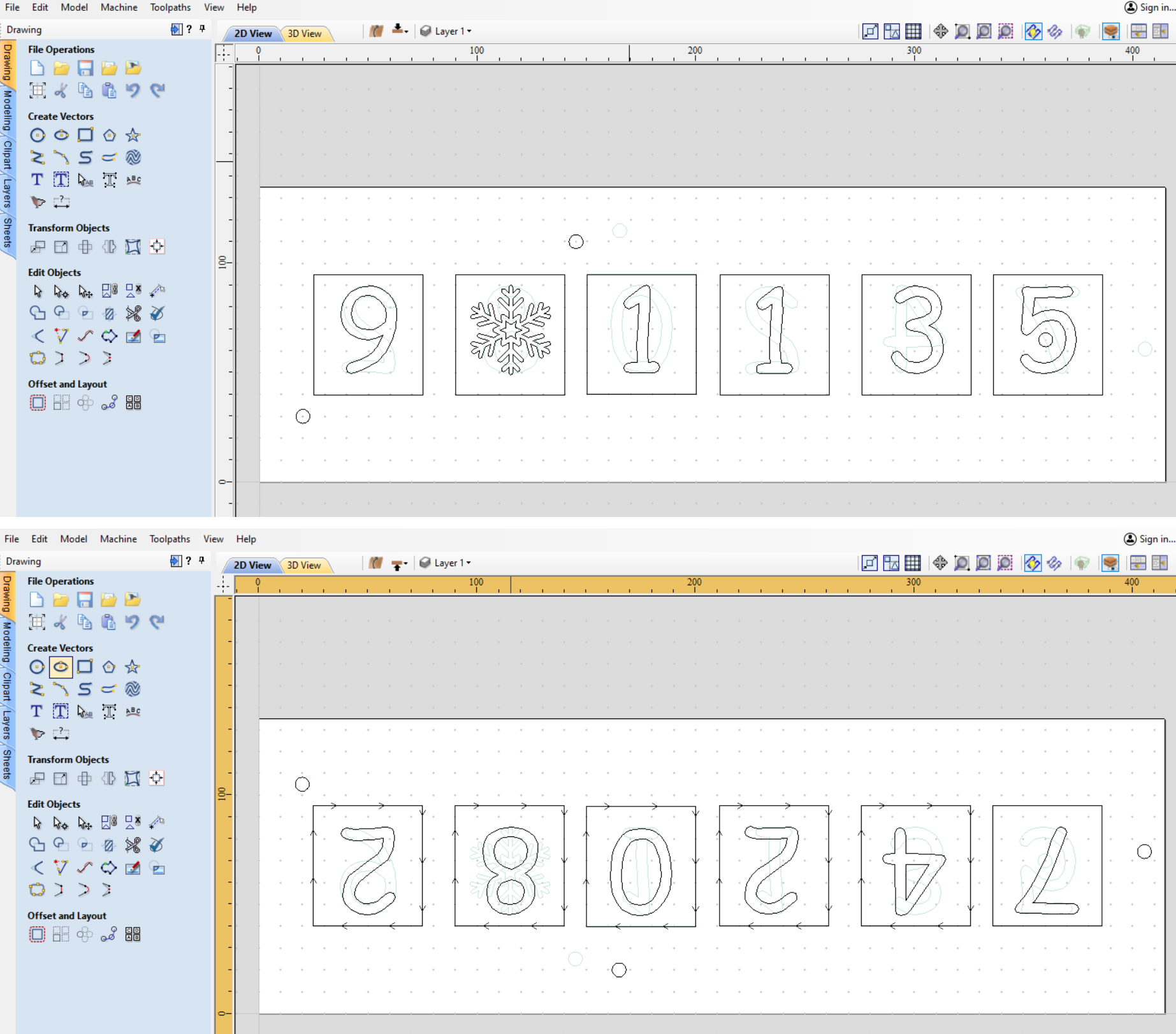

Then, I carved all the numbers using the two-sided carve feature in Vcarve. I have a 5mm recess on my base for the numbers so my numbers were not centered in the blocks. If they were centered, you could get away with leaving out the 9 or 6 because either could be flipped around. That way you would not need the additional block. I carved the extra number separately. If I were to do it again, I would have just done a 1mm deep pocket for the Number blocks and just centered them.

I used the 3 Flutes V Groove Solid Carbide 60 Degree 1/4" for vcarving and chamfering. I really like Vcarves toolpath preview. That really helped me decide on the total depth of the chamfer for the number blocks.

For the base I used the Down-Cut 2 Flutes Solid Carbide End Mill 1/4" for pockets, slots and profile.

For roughing of the 3D carves, I used the Upcut 2 Flutes Solid Carbide Ball Nose End Mill 1/4" Nano Shield and for finishing I used a 1/8” diameter ball nose end mill with a little longer reach and 1/8” shank since the sides of my house were not tapered. I cut the profiles of the 3d carved parts with a 1/8” end mill with a 1/8” shank. I also even needed to use the scroll saw on two small areas between the ears and the antlers that were too narrow for a 1/8 inch end mill. See below:

I did not use any tabs. Since these were one-sided carves, I have a fixture that I screw through and into the back of the work piece. That fixture has a matching hole pattern for the threaded inserts in my spoil board. I have found this to be the easiest way to do one-sided 3D carves. You need to be careful with how long your screws are though.

Finished Project pre-paint:

Post paint/clear coat:

Share this Project

Misterg, Ariel Yahni and Mark Carew like this.

User Comments

Sort Comments By