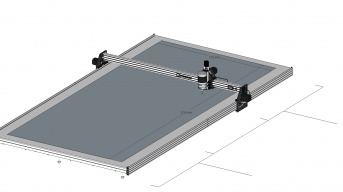

This is my initial design for a 1200mm x 2700mm cutting area CNC. It is simply a scaled up version of the ox with a SHS & EA steel bolted table as a starting point. What are the issues I may run into with this method? I would prefer not having to change the design of the plates to avoid any issues.

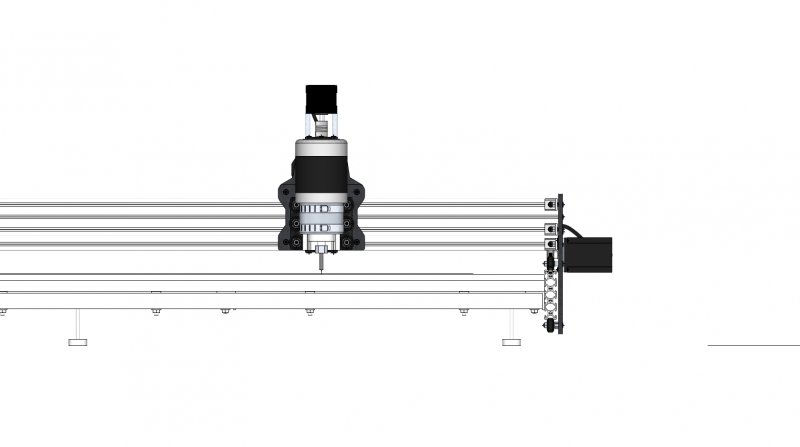

Do I need to upscale the x gantry to 2 x 80/20? It is currently the standard OX 60/20. If it was to change to the larger v-slot then I would have to modify the design of the plates.

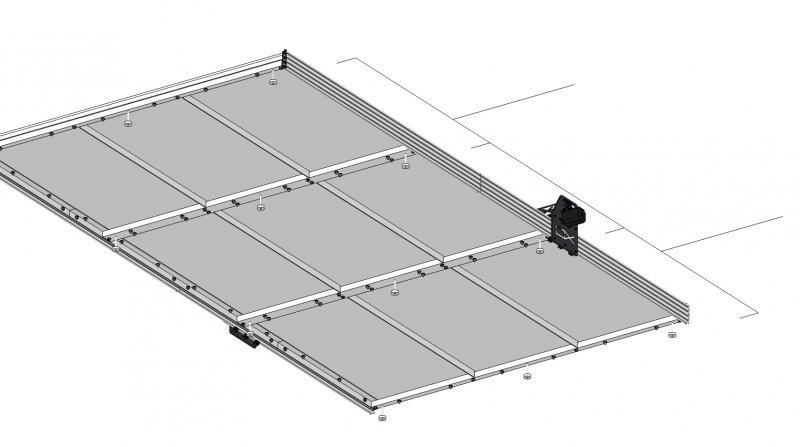

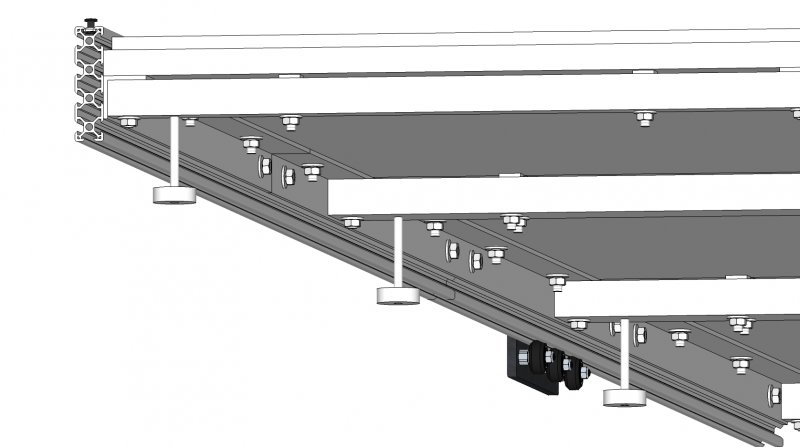

I will use 2 80/20 v-slot connected with double t nuts + fixed under table with a equal angle steel for the Y axis. Y axis is going to be rack & pinion.

Is the table too lightweight?

Nema 23 for X and Y.

Nema 17 for Z.

The location of the Y axis v-slot in relation to the table surface may be a bit low compared to the OX?

Plan view:

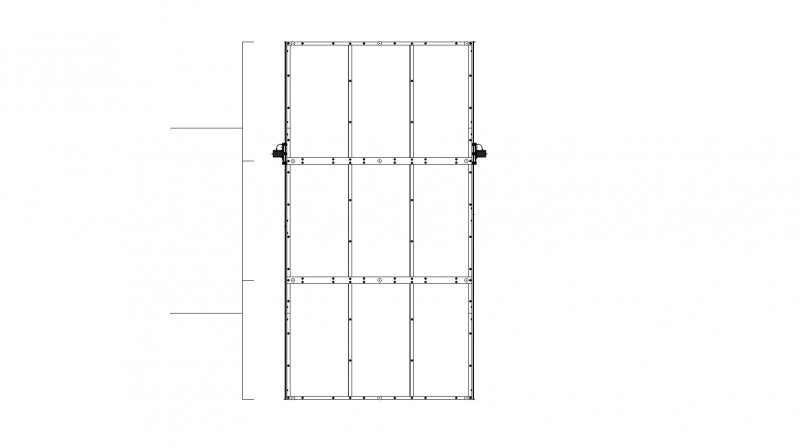

Front view:

View of table underside:

Detail view of Y axis fixing to EA, threaded table legs, bolted connections:

1200 x 2700 CNC based on OX

Build in 'Cartesian Style CNC' published by NJG, Aug 20, 2015.

Preliminary design for cnc based on OX for cutting wood sheet products (ply, MDF etc.) for a sheet size of 1200mm x 2700mm

-

-

-

- Build Progress:

-

- Build in Progress...

-

-

Build Author NJG, Find all builds by NJG

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Inspired by

Original OX