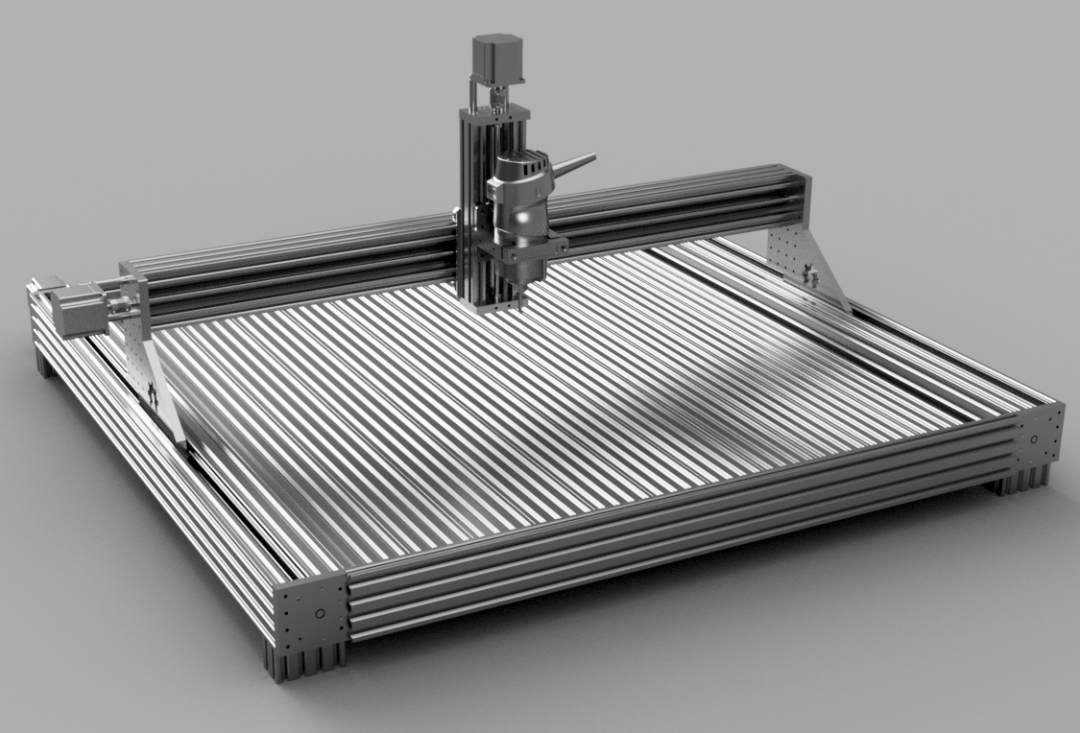

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000.

This build is just starting. This is my first build based on my own research and help here on the forums. My current CNC machine is a C-Beam that I got as a Kit from Openbuilds.

Motivation and Goal : Be able to carve larger boards and also mill aluminum plates.

The design priorities for this build are

1) Resilient - Needs to be at least as resilient and powerful as my current C-Beam machine (Which is awesome by the way.)

2) Dust Protection - Try to protect the tracks against dust as long as the solution does not compromise on performance. The final build will have the dust shoe that I designed for my C-Beam.

3) Looks - Needs to look **** awesome and sleek of course

4) Price - You cannot get all the above without compromising on something. This will not be a cheap build and I will also add more finishing details after the main machine is completed.

PS : This build currently uses two custom plates, but I will design more to allow more flexibility. I modeled them inspired by some OX, Sphynx and Larger C-Beam builds. The parts are the side plates for the X Line Actuator that runs along the Y axis and the end plates for all the linear actuators, so I can properly mount all four screws from the stepper motors. I will submit detailed plans after I mill the parts and make sure they work.

Here follows a link to my current build. Will update it as the project matures. A360

Credits : This build was inspired by several builds from Openbuilds website, however was heavily based on Gino's build : (C-BEAM-GTC) and C-Beam Machine (C-Beam™ Machine - Plate Maker).

C-Beam Machine upgrade to 1000mm x 1000mm

Build in 'Cartesian Style CNC' published by Cleyton Alencar, Mar 29, 2017.

This built is to convert an existing 500x500 C-Beam Machine into 1000x1000. Inspired by several builds including C-Beam Machine : (http://www.openbuilds.com/builds/c-beam%E2%84%A2-machine-plate-maker.2020/) and Gino's build : (http://www.openbuilds.com/builds/c-beam-gtc.3250/)

-

-

Angela Warner, Jay Lytle, Mark Carew and 1 other person like this.

-

Build Author Cleyton Alencar, Find all builds by Cleyton Alencar

-

- Loading...