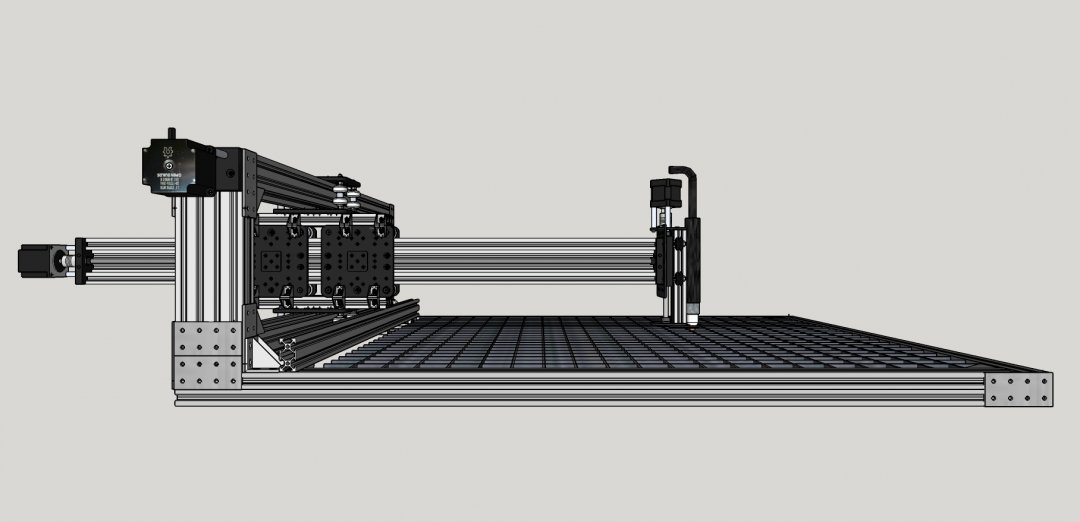

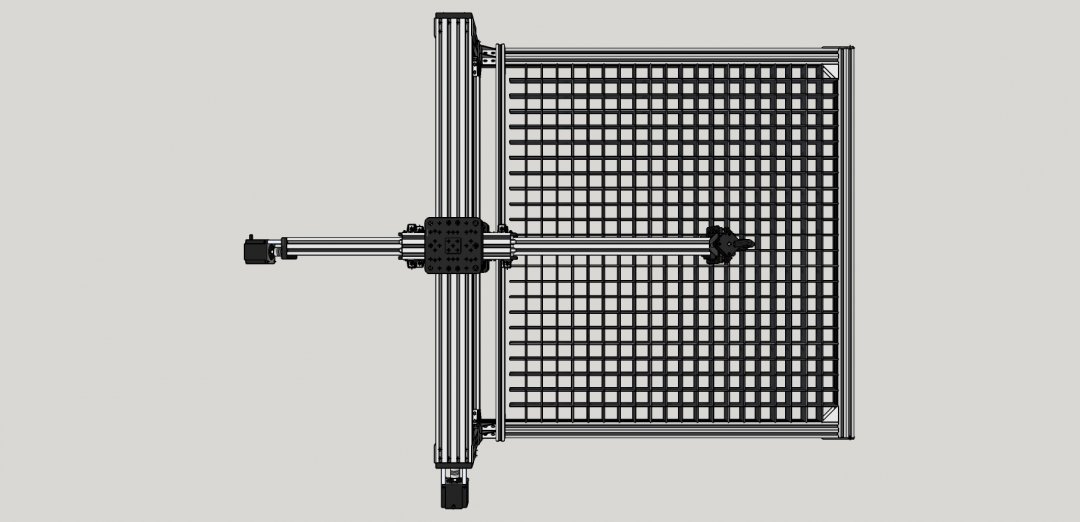

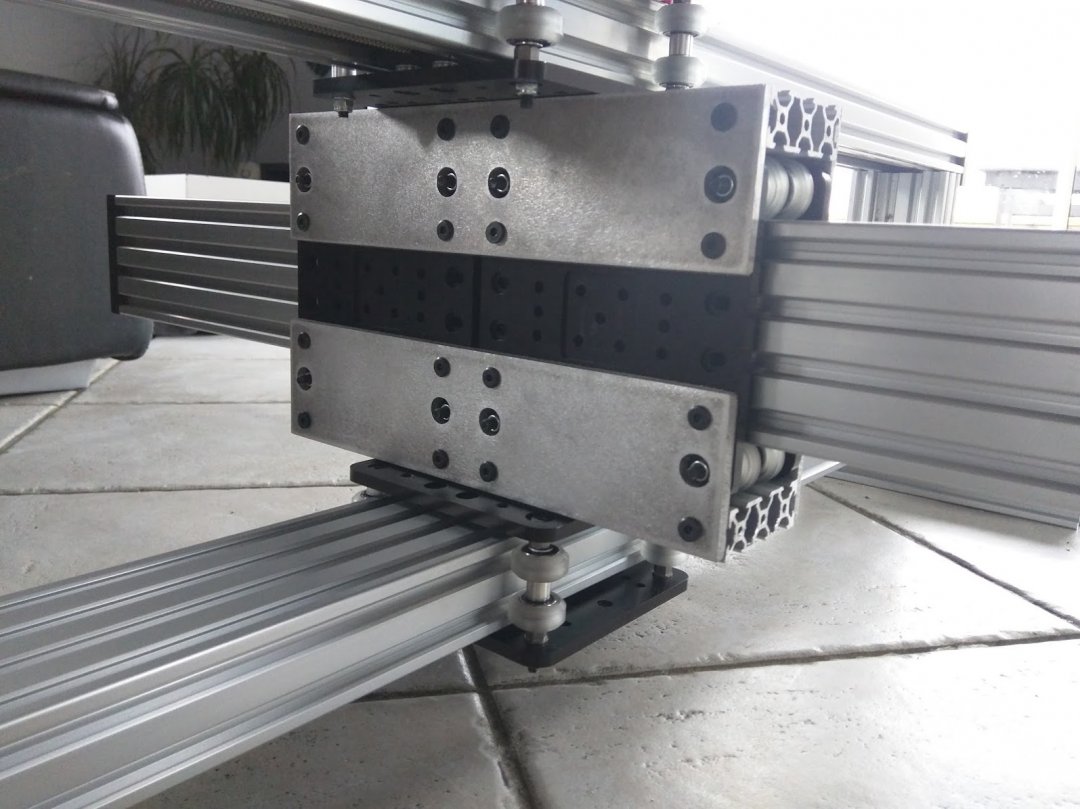

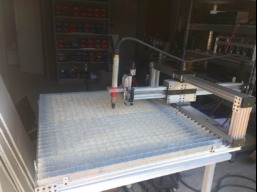

I already have a plasma cutting table made with openbuilds products , but when i saw the metalguru's idea , i said "whoaww" , this build will be perfect for me .

A compact plasma cutting table , easy to carry . neither to big nor to small

I will describe here the advance of this assembly

First : The idea ( picture from Metaguru )

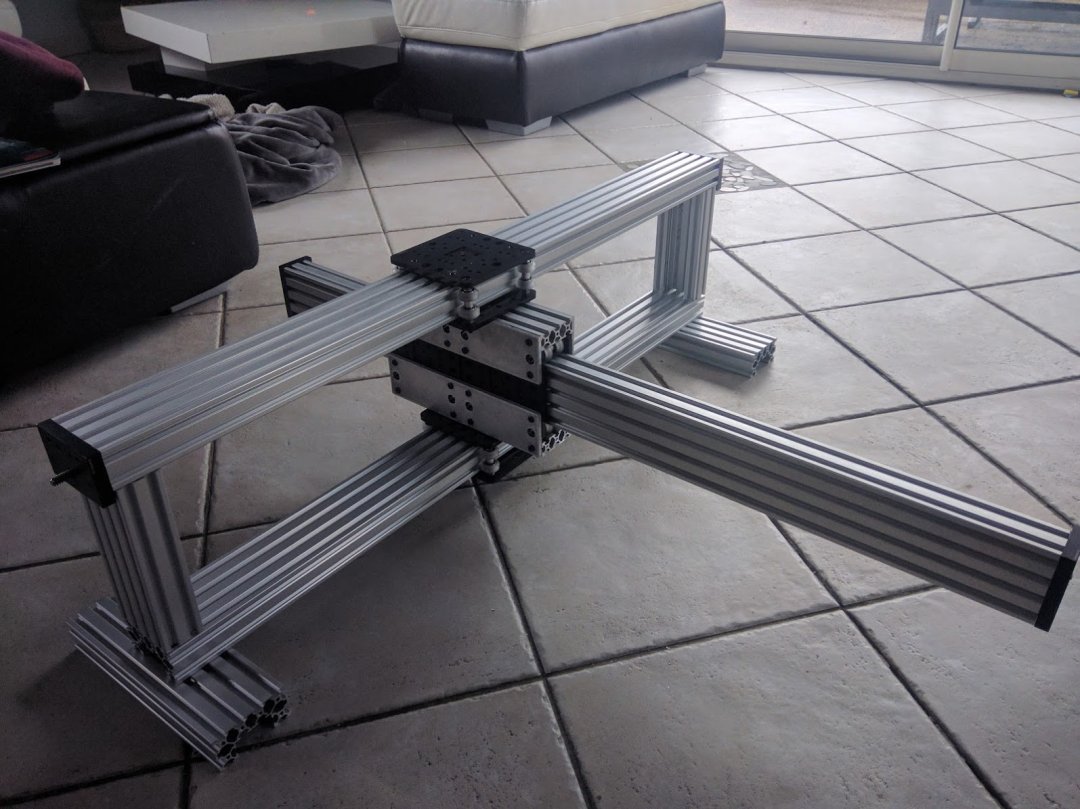

And now , let's go working :

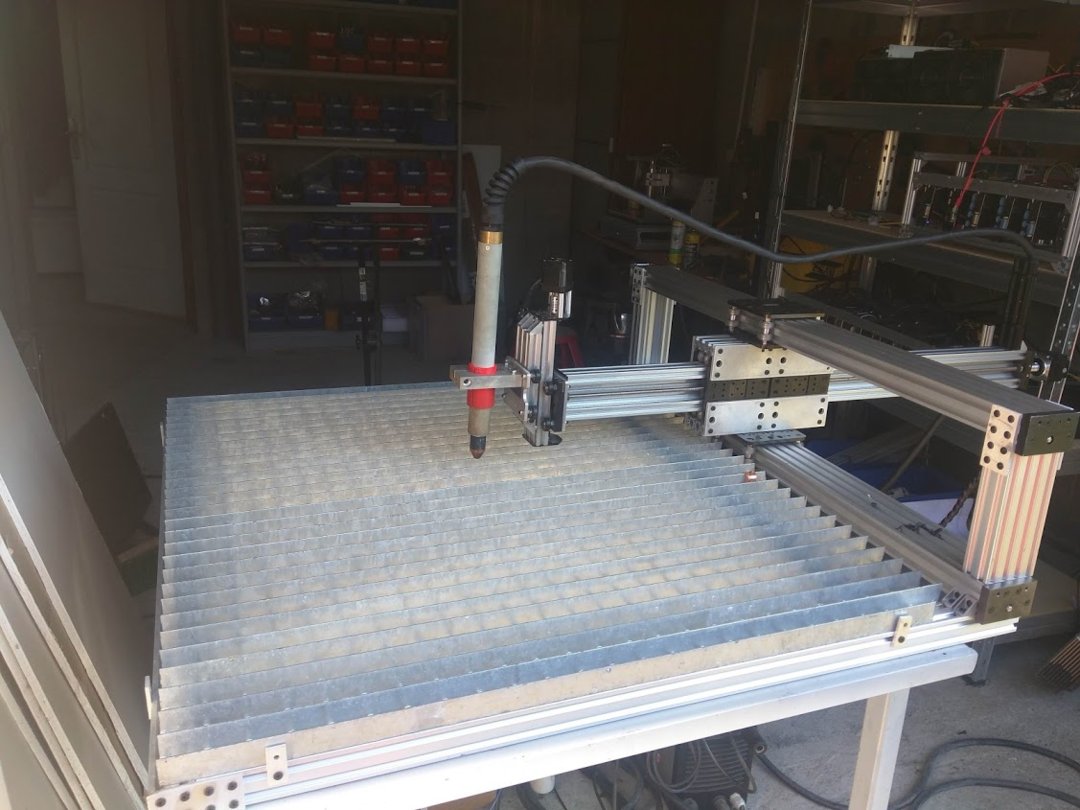

Plasma generator will be an Esab Cutmaster A40 or A60 .

The A-serie from Esab is perfect for this kind of use .

CNC control board is already build in , Torch will be a mechanical one (SL 180 from esab )

I will not add a THC on this project because the working area is not really big so it's not needed here.

Stepper motors will be High torque Nema 23 for X and Y axis and nema17 for Z axis .

For the torch , i'm not sure at this point if i will use a floating head or an inductive sensor to detect the material .

Updated : May 2nd 2017

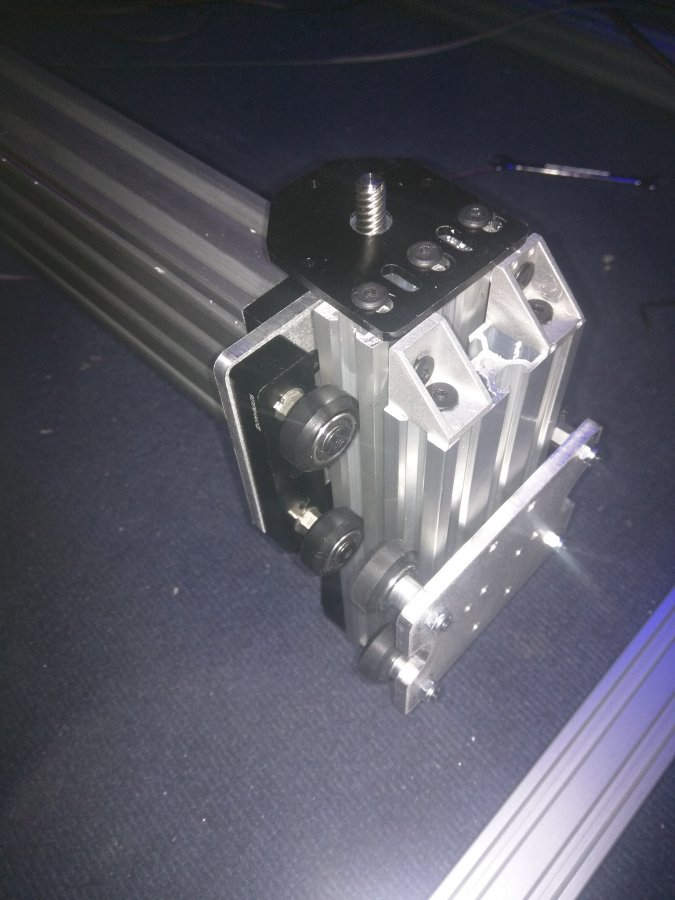

I take the decision to use I a floating head instead an inductive sensor , because inductive sensor is too expose and can be parasite by plasma arc .

Floating head picture :

Wiring is done .

Some pictures ... first video coming soon

I come back to this project with some mods , ( i add a second stepper on the X axis and some other small enhancements).

First moves :

new picture :

First cut , this project is finally finished

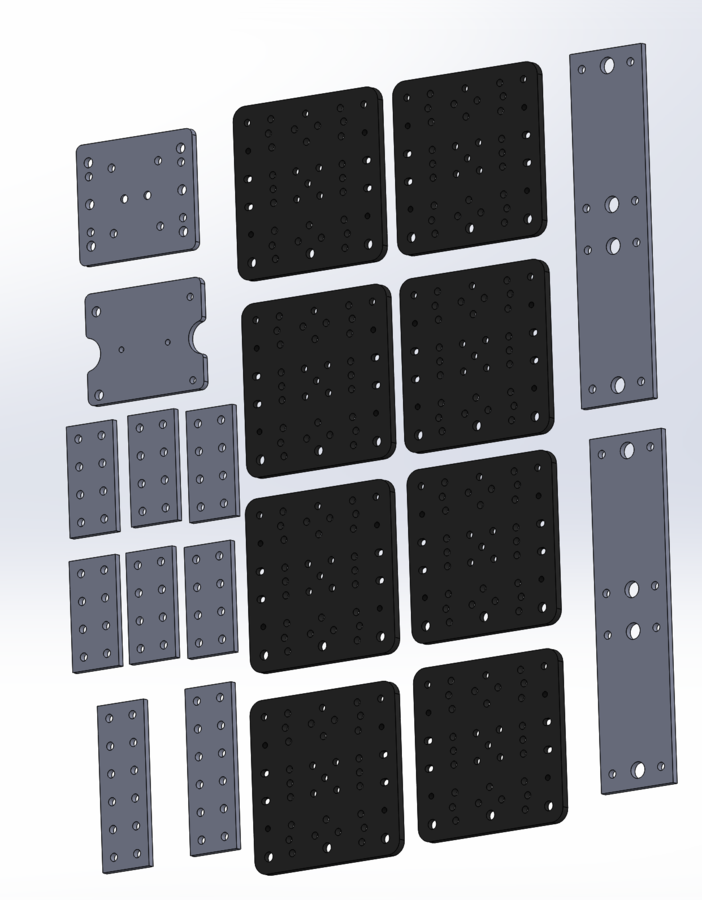

All plates you need ..

Dragon Plasma cutter

Build in 'Plasma Cutter Builds' published by mytechno3d, Oct 8, 2018.

Inspired by MetalGuru's idea : The plasma too cutter . If you have to cut small to medium sheet of steel with a plasma , this build may be for you

-

-

-

- Build Progress:

-

- Build Complete!

Attached Files:

Kjellski, samir alsurihi, joaquin gutierrez and 38 others like this. -

-

Build Author mytechno3d, Find all builds by mytechno3d

-

- Loading...

-

Build Details

- Build License:

-

- GNU (GPL3+) General Public Licence

Reason for this Build

I need a portable plasma cutting table .Inspired by

-

Parts list

-

Attached Files:

-

![[IMG]](https://openbuilds.com/styles/default/xenforo/clear.png)