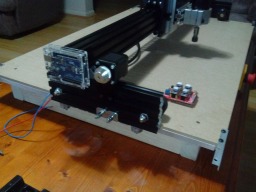

I decided to build this CNC using the Crawlbot as my inspiration. It uses double 6020 vslot with a slightly modified OX CNC plate gantry. The Y system is made of 8020 with attached skateboard wheels and delrin wheels. The electronics are nema17 70oz motors connected to the Uno/CNC Shield setup. The spindle is an air cooled 500w spindle. I am running the GT2 belt on the outside (the reasoning for this is too keep it clear of the workspace and easily accessible) but there is the option to turn the motors around and run the belts on the inside if needed.

I am currently in the building process of the 1metre wide unit, and a 1.5 metre wide unit that has a double 8020 x axis. These are my 4th and 5th CNC builds, and what I love about this project is a number of things. The baseboard (or waste board) comes from the hardware in standard sizes. So the one in the pictures is a standard 900mm x 600mm MDF board. Perfect size for Desktop in my study. If I want to do something bigger, I can walk the gantry down to my workshop, where I can put it on a 900 x 1800 MDF Table. The Y ends of the MDF are lined with a alumium angle (a few dollars a metre from the hardware), this is so the side bearing have a solid surface to run on, rather than the edge of the MDF.

The 1.5 metre gantry will be running nema23 steppers and a tb6660 controller using MACH3. Waiting for more parts to come in, so will update as I go along and better photos.

UPDATE: 30/3/17 Belts arrived today. Its only 6mm wide, but made sure it was re-enforced (wire). Still waiting for bearing pulleys, but installed a couple of bearings just so I could put belts in place. Taken a few photos of the left hand side, I will do the other side when the pulleys arrive as i don't have any spare bearings. Also installed the Emergency Stop. When I started this project, I was designing this CNC with endplates (Which I started milling out), but I decided to go with 8020 V-Slot to ran the Y-axis, because I realized it gave me the option to place the X-axis and motors in any configuration I wanted.

UPDATE 1/4/17 A couple more photos just to show it packed away when not in use.

UPDATE 21/5/17 Just another update on the progress. I ended making the waste board into a work bench, as I was getting sick of bending over the coffee table while working on it. This is only til i get the concept working, then it will move onto a 1800 x 900mm work table. I have been concentrating on cable management and almost ready to power up for movement. I have a spindle controller that will be in a black plastic case ready to attach and my vacuum system down below. So more photos as well and hopefully a video soon.

UPDATE 13/6/17. Well shes alive. I am using the DRV8825 Drivers on the CNC Shield and had a problem at 1/32 step. Spent ages trying to adjust the Vref, but couldn't get rid of this slight clicking sound in the motors. Changed it to 1/16 steps and was all good. Put some cooling on the board, 3D printed out a Z-Axis Motor Support, and attached a small monitor to the bench. I did a few dry test runs and went well so far. Some more photos, and will get a video of it doing a dry run up soon. Next : Will wire up the Spindle hopefully this week.

UPDATE 9/7/17. Complete and finished. Cut a test square and circle (40mm) and measured at 39.8mm. I started cutting out a doll house for my grand daughter today (plans from MakeCNC). Did 2 sides, and 2 lugs and fitted perfectly. 3mm MDF with 2mm dia 2 flute carbide bit at 10mm/sec. going in .8mm depth per pass. 500 watt spindle. Later on I will transfer the Gantry onto a larger table (1800 x 900), but for the time being I will start working on my larger version of this.

Inspired by the Crawlbot

Build in 'CNC ROUTER BUILDS' published by Craig, Jul 9, 2017.

Building a couple of CNC's based on the Crawlbot

-

-

-

- Build Progress:

-

- Build Complete!

Attached Files:

Lister F/X, DM05, Maurice_CNC and 19 others like this. -

-

Build Author Craig, Find all builds by Craig

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

![IMG_20170613_102121[1].jpg](data/attachments/24/24966-b2ccfb88fd853dd6a00805a1df1ddb07.jpg)

![IMG_20170613_102105[1].jpg](data/attachments/24/24967-3b8265a63907ad8b8eaed963fa535e88.jpg)

![IMG_20170613_102049[1].jpg](data/attachments/24/24968-2844f44017ddc40fbf7761c2d7707088.jpg)

![IMG_20170613_102000[1].jpg](data/attachments/24/24969-fc5d69eccbb22f7de2c96b71cee75157.jpg)

![IMG_20170613_101933[1].jpg](data/attachments/24/24970-b2b2a1ad55aa576426b6b465d5e29035.jpg)

![IMG_20170613_101922[1].jpg](data/attachments/24/24971-140bd0e2aea362123b2f8435ca33d745.jpg)

![IMG_20170708_071642[1].jpg](data/attachments/25/25456-2797cf550350b042d23e620eea010963.jpg)

![IMG_20170709_065715[1].jpg](data/attachments/25/25457-821218eaa4002e462d4fe0d46ce5b1ab.jpg)

![IMG_20170709_080701[1].jpg](data/attachments/25/25458-ddd805b1de4ab7d85e74260c9a51d2d8.jpg)

![IMG_20170709_065735[1].jpg](data/attachments/25/25459-4427f64d210a952e60489981a3a1138d.jpg)

![IMG_20170709_082400[1].jpg](data/attachments/25/25460-baf2dc15a40bcf8c26784f1f486bf0e5.jpg)

![IMG_20170709_082751[1].jpg](data/attachments/25/25461-70bcda4b7bd32240180f53f1ed9e5328.jpg)