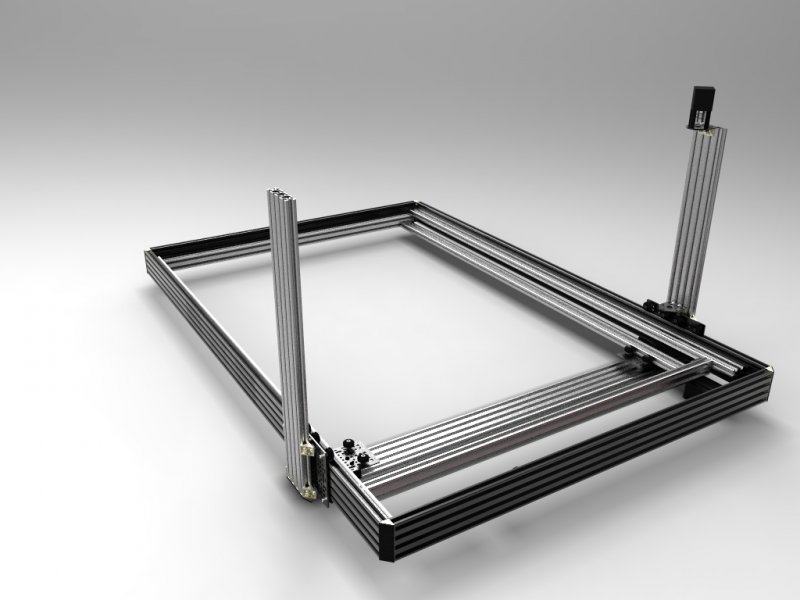

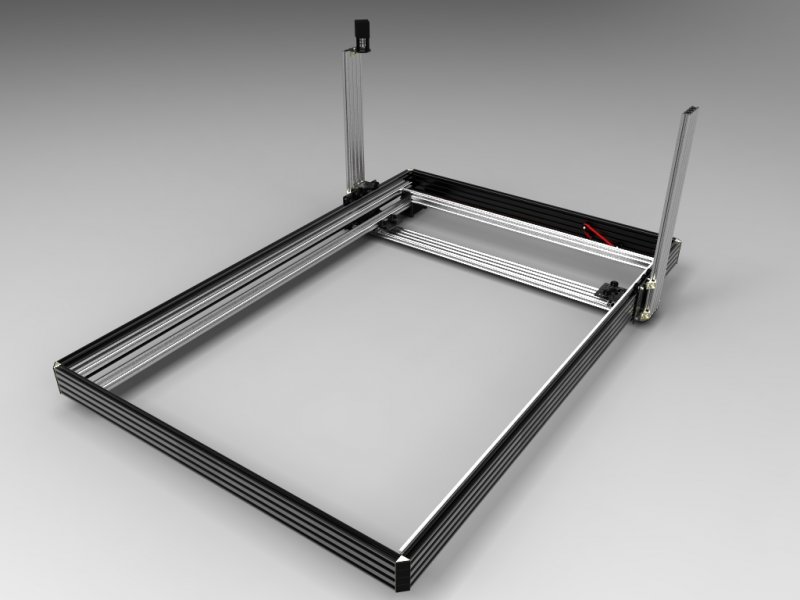

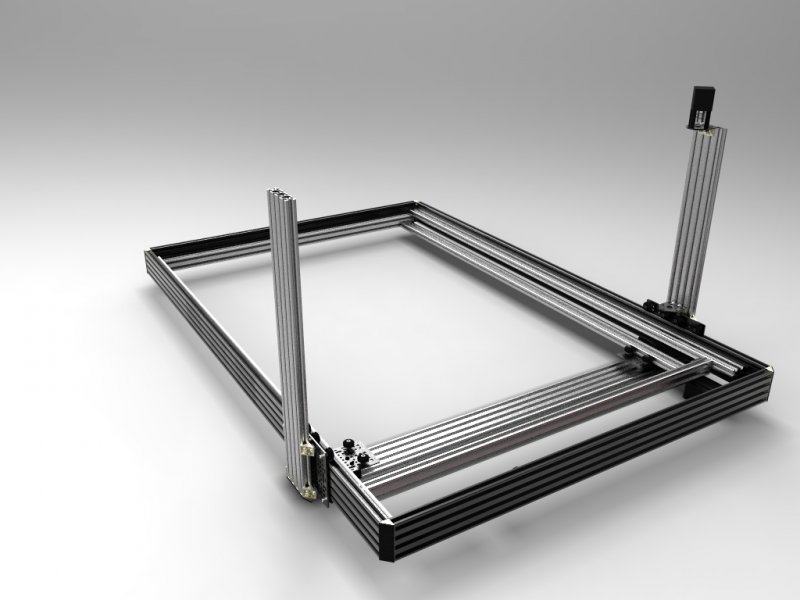

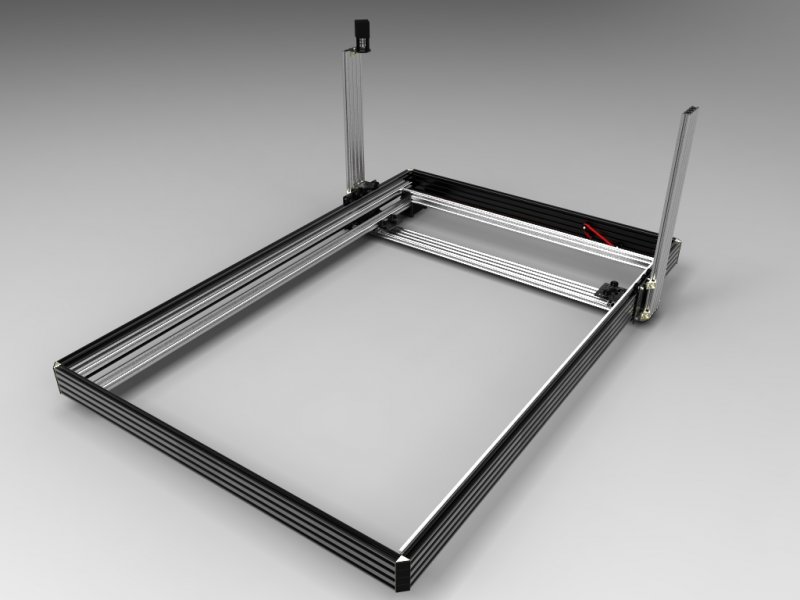

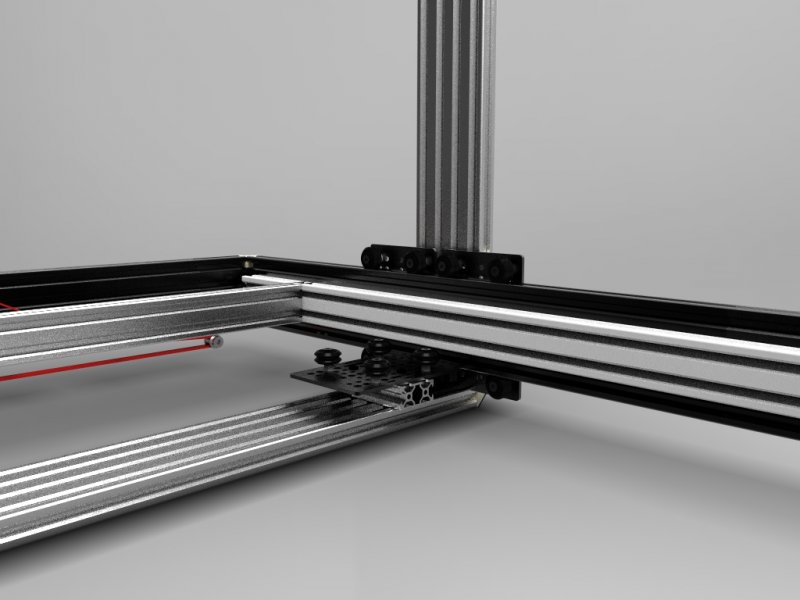

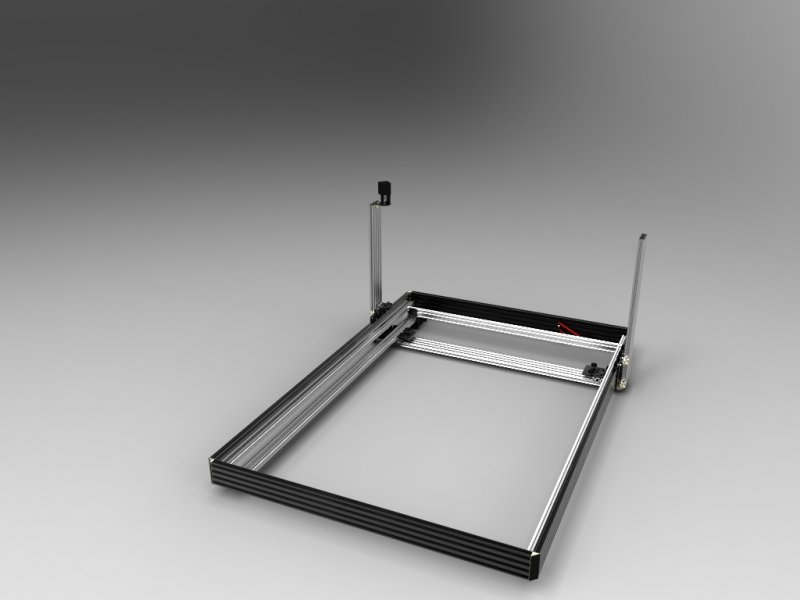

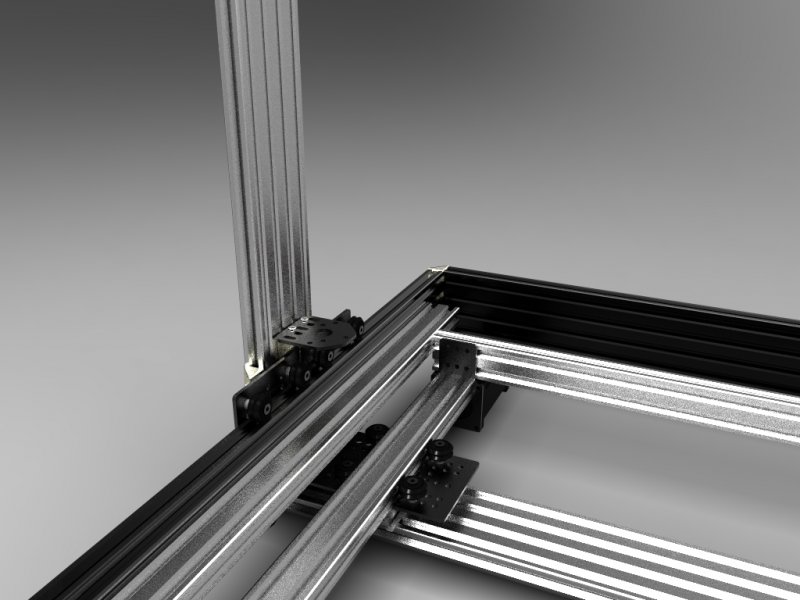

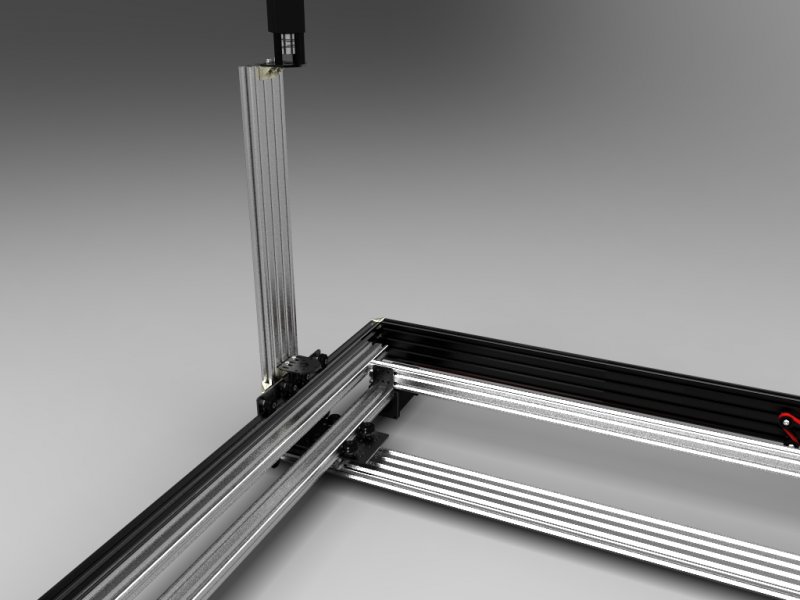

This design is not finished yet but you can get a good idea of where I am going with this. It has been built for a client that wanted maximum area based on the profiles. The design can easily be adapted to be a CNC machine quite easily. The design as it stands can use the entire X and Y axis profile lengths as the cut area so this one is X750mm x Y1500mm but bigger or smaller designs can be adapted from this.

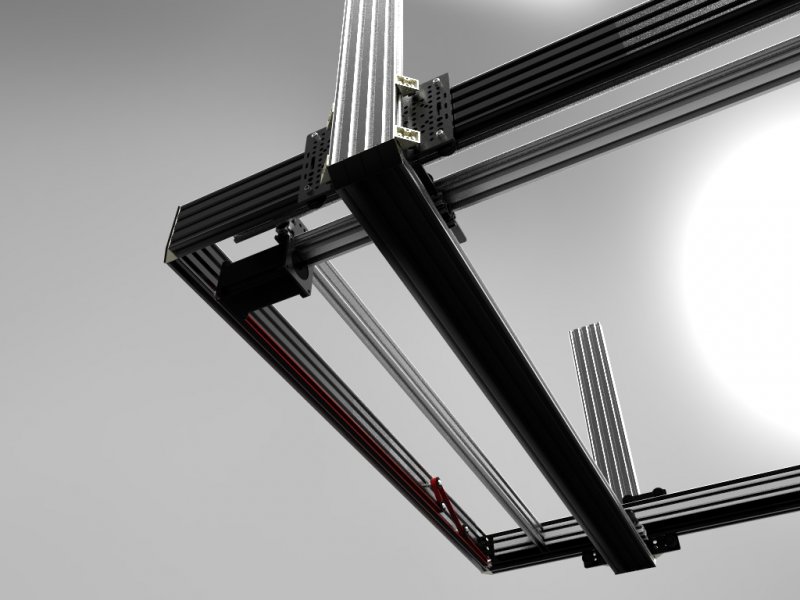

The X/Z axis are independent on this design and the arms are long purposely but again they can be shortened and a motion X axis applied easily. I will model both the CNC and the Foam cutter with this build.

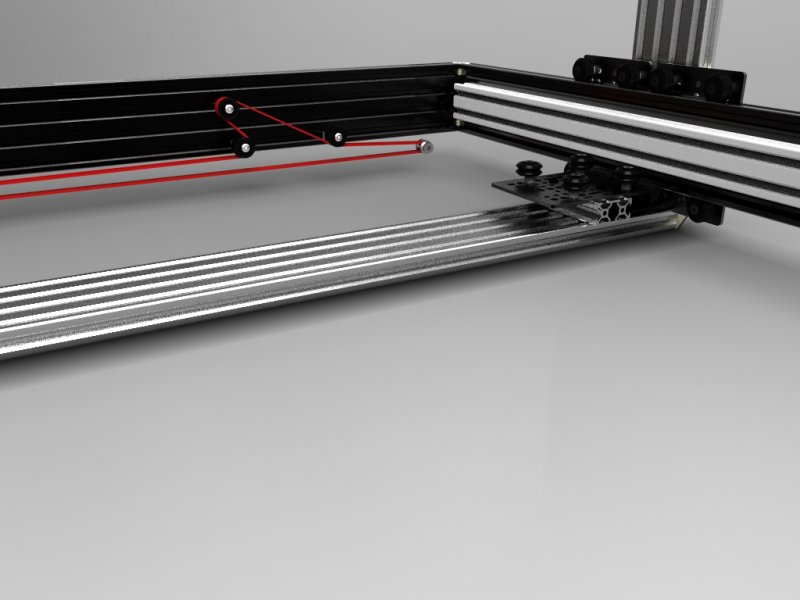

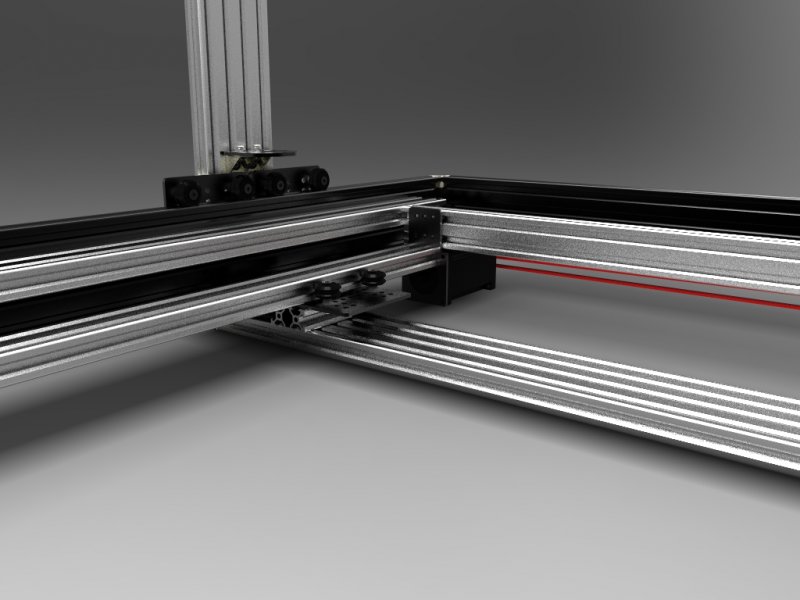

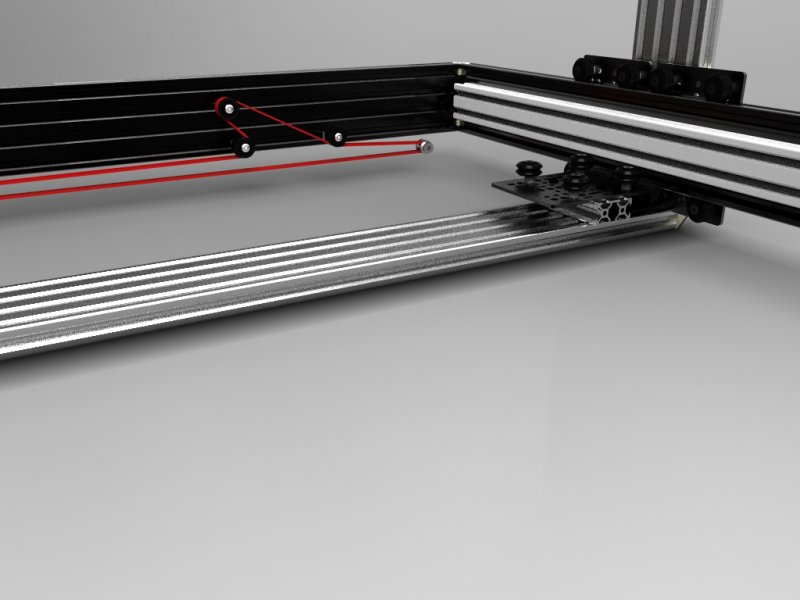

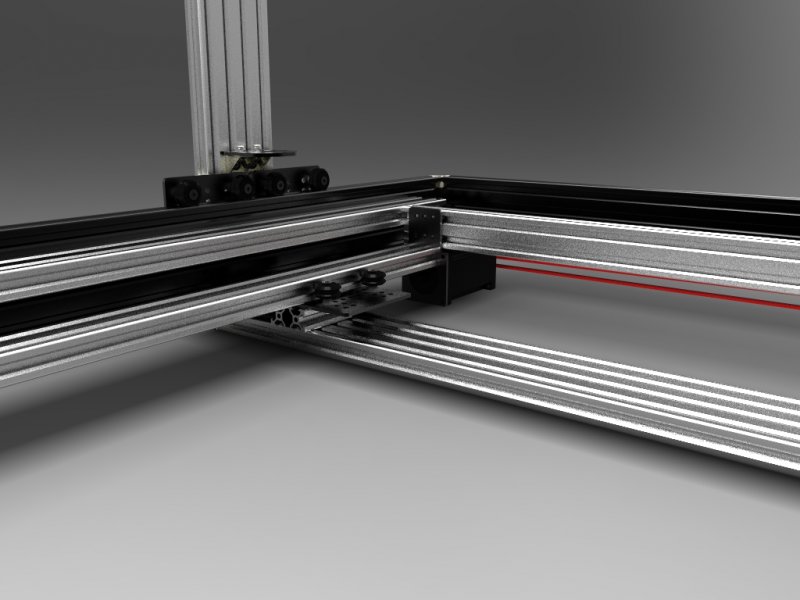

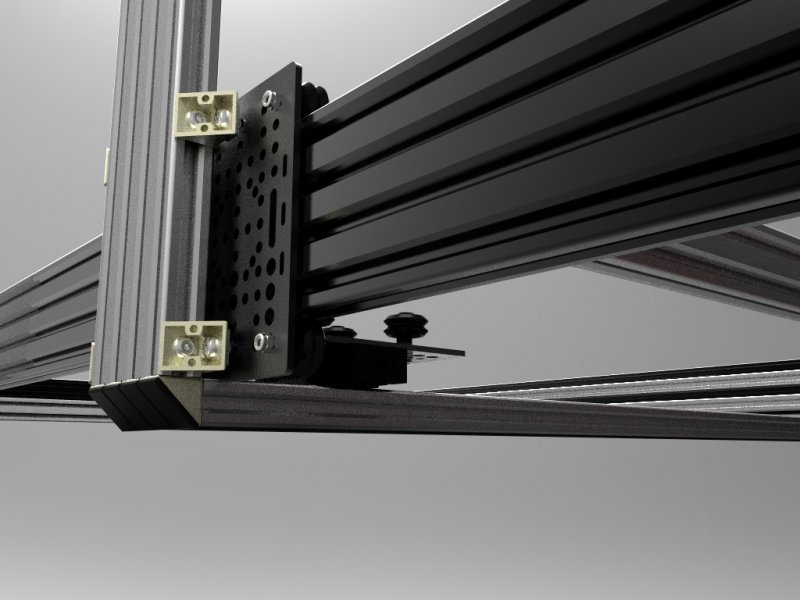

The Y axis is powered by a double shaft Nema 23 motor, on which one side (the long side) has a leadscrew attached (required by the client), the short side has a pulley attached and a belt which is attached to another pulley on the other side of the machine which in turn is attached to another leadscrew so as the motor rotates both leadscrews move together. The Z Axes are Nema 17, using Openbuilds Threaded rod plates mounted to the side of the profile with 90 degree cast or openbuild aluminium supports rather than mounted on the top of the profile.

I have not yet decided what type of belt and matching pulley would be best for the machine so any ideas are welcome as are comments positive or negative about the build.

The 'bed' can be positioned on the Y 2040 mounts but I think these made need strengthening to support any decent weight, especially on this MAX size. Of course multiple bed supports can be added easily.

check out this flimsy video to see how it should work when feet or supports are added to the bottom of the frame: http://www.robocutters.co.uk/RoboFoamCutter.swf

RoboFoamCutter

Build in 'Cartesian Style CNC' published by Colin Russon, Feb 6, 2014.

Lead screw based Foam Cutter that can easily be adapted to full belt / pinion drive and to CNC.

-

-

-

- Build Progress:

-

- Build in Progress...

komsunudf, Seul Kee, Pawlenko M and 1 other person like this. -

-

Build Author Colin Russon, Find all builds by Colin Russon

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - CC BY NC

Reason for this Build

Built from a client request for a Foam Cutter design based on V-Slot -