Hello fellow builders

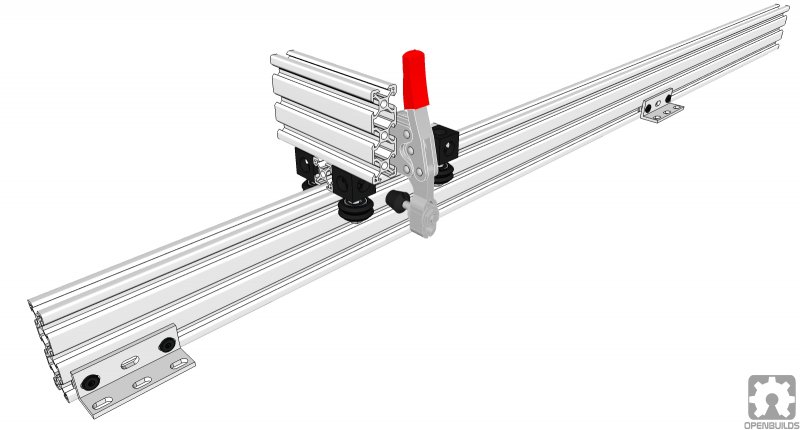

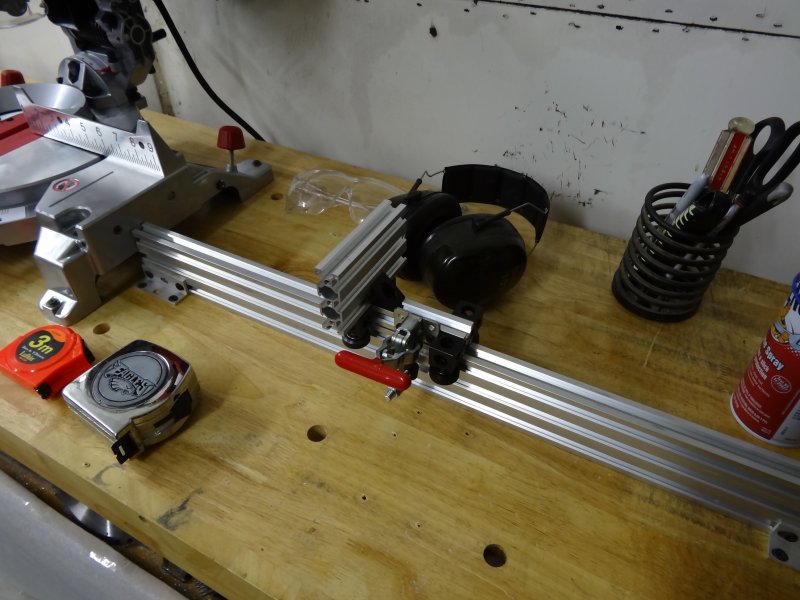

Here is a simple saw stop to help when you have multiple cuts of the same size to make in V-Slot for example. Of course, it can be used for many material types as well - not just extrusion.

I threw this project together in about 20-30 min from the time I took the saw out of the box, so its not going to win any design awardsJust needed it to do the job, and it does. Its quick and easy to use!

So, the concept is to move the first material that is need to cut into position. This is the material with the mark for the cut. Roll the saw stop up to it and lock it in place. Make your cut and repeat, simple as that.

There are a lot of areas for improvement on this project and maybe a complete redesign, so please feel free to run with it and make it your own

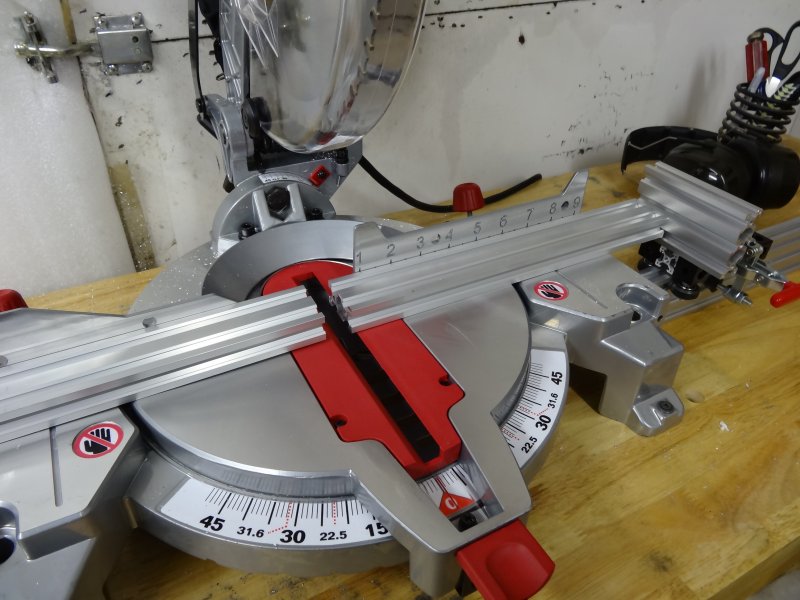

Picked up this 10" miter saw from LOWES for about 120 bucks

http://www.lowes.com/ProductDisplay?productId=3305832

Grabbed a 10" metal cutting blade while I was there as well. I think there are better blades on line but I wanted to get up and running so I went for it.

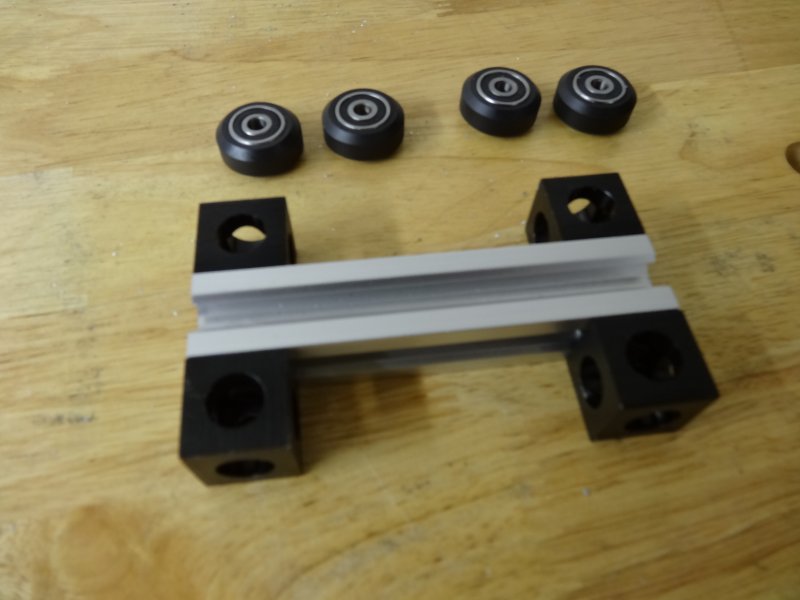

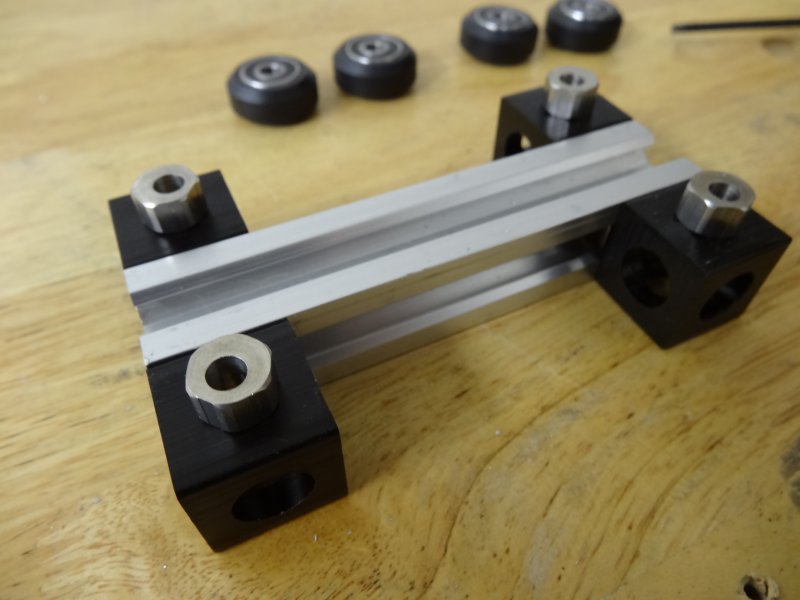

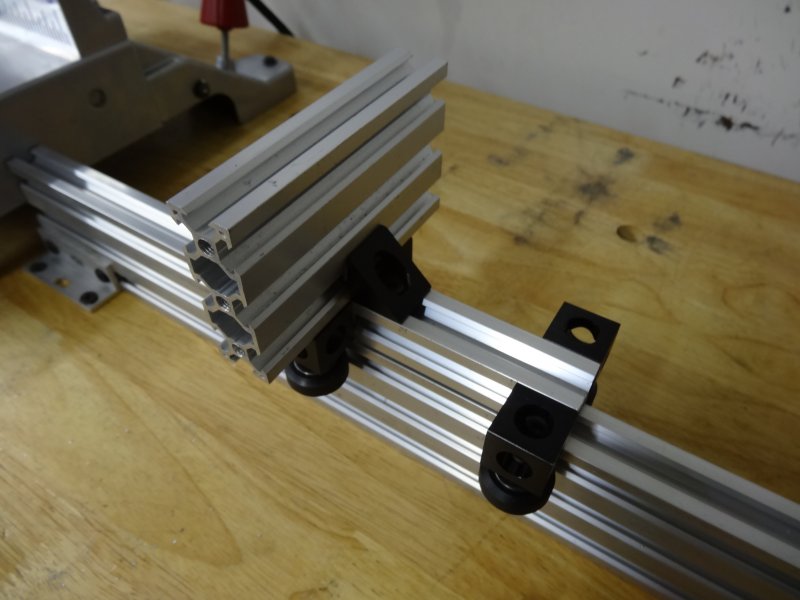

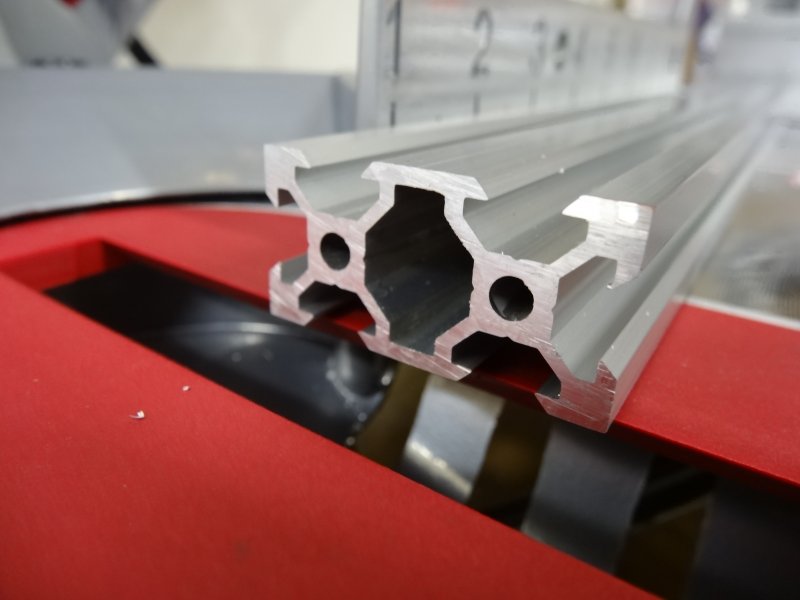

Building up the slide cart. I used 3 way corners for this as they are really easy and quick to work with

Test fitting the eccentrics. Sometimes they can be a little tight and need a little persuading but these went in just fine.

Note: You will want to turn two of the eccentrics on one side of the V-Slot cart toward each other and tighten them in place. This will set the eccentrics at about the halfway point in the rotation. Later in the build you will put the V-Slot cart in place and turn the opposite eccentrics to lock the cart on the rail.

Took the saw out of the box and changed out the blade to the new metal cutter.

Measured from the front of the table back to set the saw when I wanted it.

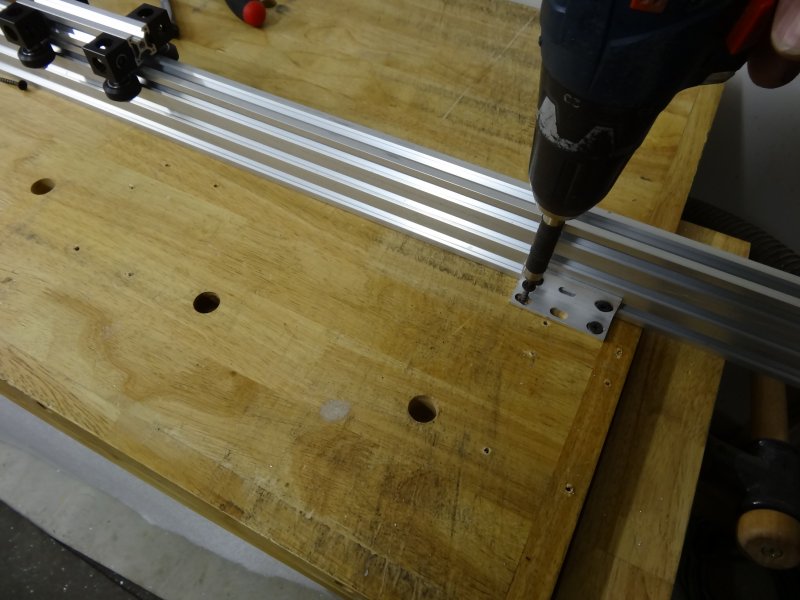

Using wood screws and washers I mounted the saw to the table

Saw is mounted to the table.

Added triple L brackets to 20x60 V-Slot.

Measured from the front of the table to approx the center of the saw table and screwed the L brackets to the table. Found that I only needed to used the two outside holes on the L brackets.

Top view before screwing the rest of the bracket to the table.

Measured from the front of the table same distance as the front L bracket and added the back L brackets. Keeping the V-Slot guide parallel with the saw.

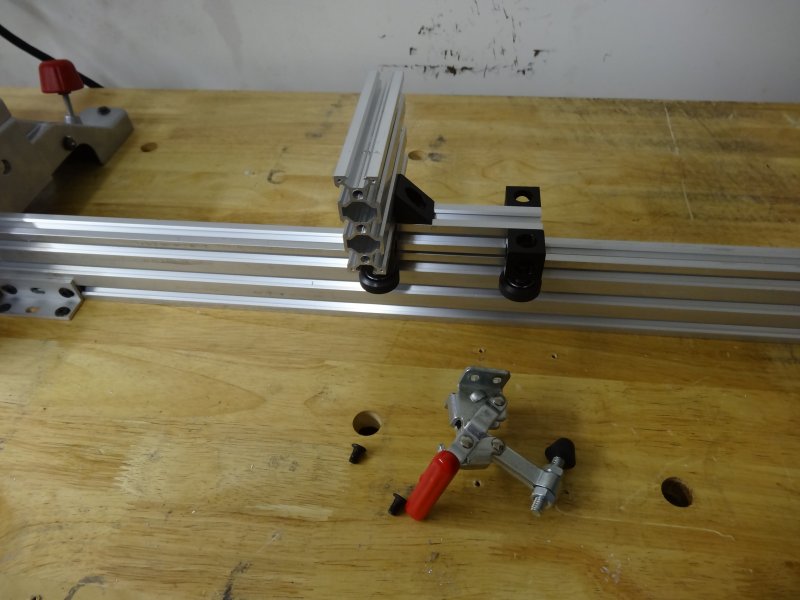

Added the V-Slot cart from the back and tightened down the two eccentrics, locking the VSlot cart onto the rail.

Also added the 'stop' piece of V-Slot using a single corner block.

Front view of the saw stop

Testing the VSlot and tweaking the eccentrics to ensure it rides smooth.

Getting ready to mount the clamp.

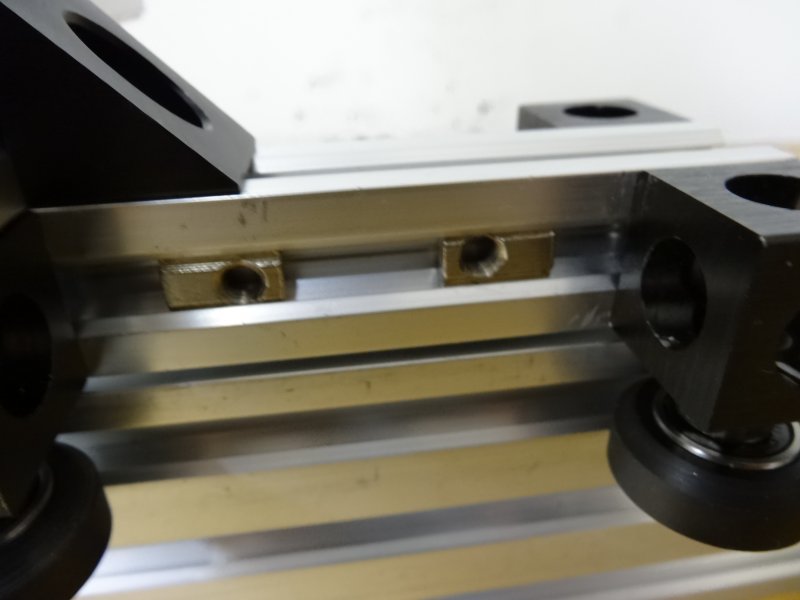

Push-in spring nuts for the clamp mount.

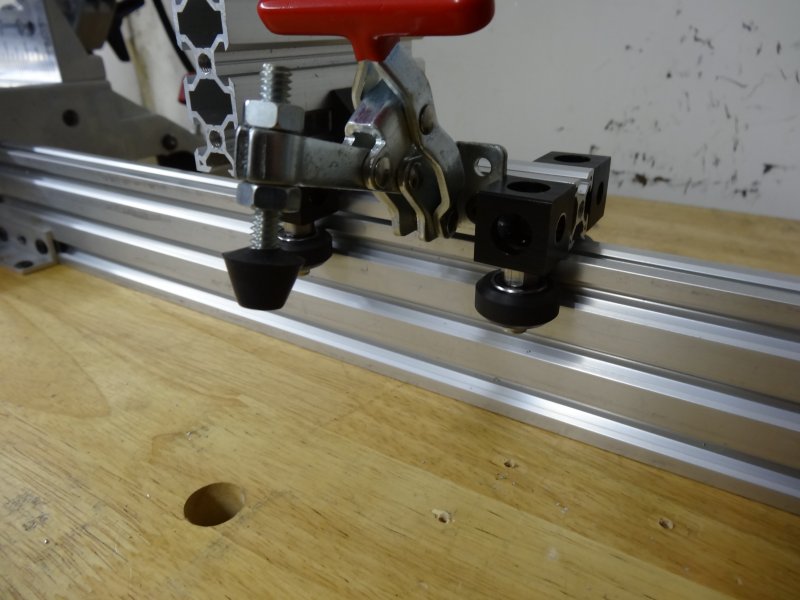

Lining up the clamp with the bottom holes.

After the clamp is screwed in place make sure to adjust the rubber stopper screw (using the two nuts) for a tight clamping force, but not so tight it pulls the rail to one side.

Just enough to lock it from moving and gives you a good stop to run material up to. Once you get it set you can tighten the two nuts to make sure it does not come lose down the road.

Another view, everything is in place and ready to go.

Getting everything set up for the first cut.

First cut works perfect!

Another view (will hook up the shop vac in the future)

Quick video moving the cart and show how it locks into place

Well, that's it for this simple build.

Like I said there are many ways to improve on this, so please do and share it.

Hope this helps out with cutting for your upcoming projects!

V-Slot Miter Saw Stop

Build in 'Everything Else' published by Mark Carew, Dec 28, 2017.

A quick and simple saw stop build.

-

-

-

- Build Progress:

-

- Build in Progress...

-

Special Notes

Need to build the 3D model and add a parts list to complete

Always ware proper safety equipment when working with power tools and follow the tools safety manual for correct use.

-

-

Build Author Mark Carew, Find all builds by Mark Carew

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution Share Alike - CC BY SA

Reason for this Build

We needed a way to quickly change cuts while being able to cut multiple cuts accuratelyInspired by

Saw stops -

Parts list

Qty Part Name Part Link Comments 4 Triple L Bracket http://openbuildspartstore.com/l-bracket/ Link These will hold the main slid rail to the table 4 Cube Corner Connector http://openbuildspartstore.com/cube-corner-connector/ Link Used on the gantry slider 4 Solid V Wheel Kit http://openbuildspartstore.com/solid-v-wheel-kit/ Link Wheels for the cart 4 Eccentric Spacer 1/4" http://openbuildspartstore.com/eccentric-spacer/ Link Used on the gantry cart to tighten the wheels to the V-Slot 4 Low Profile Screws M5*25mm Singles http://openbuildspartstore.com/low-profile-screws-m5-25mm... Link Used on the Wheels 1 Black Angle Corner Connector http://openbuildspartstore.com/black-angle-corner-connector/ Link Used on the back of the V-Slot Stop 2 Spring Loaded Tee Nuts http://openbuildspartstore.com/spring-loaded-tee-nuts/ Link Used to mount the stopping clamp 1 Vertical Quick-Release Toggle Clamp http://www.amazon.com/POWERTEC-20303-Vertical-Quick-Relea... Link Used as the cart stop (many styles will work) 1 Tee Nuts (25 Pack) http://openbuildspartstore.com/tee-nuts-25-pack/ Link Use throughout the build 1 Profile Screws M5 (8mm) http://openbuildspartstore.com/low-profile-screws-m5/ Link Use throughout the build 1 V-Slot 20mm x 20mm V-Slot (4") http://openbuildspartstore.com/v-slot-linear-rail/ Link This is the short piece of 20x20 V -Slot I used 4" for mine (had it left over from a build) 1 V-Slot 20mm x 60mm Linear Rail (1000) http://openbuildspartstore.com/v-slot-linear-rail/ Link Cut 4" from the end of this V-Slot to use as the saw cart stop piece 8 Self Tapping Screw http://openbuildspartstore.com/self-tapping-screw/ Link Used to screw the main 20x60 V-Slot to the work table -

Attached Files:

-