Another Aluminium OX - Just started

Discussion in 'CNC Mills/Routers' started by sgspenceley, Dec 5, 2014.

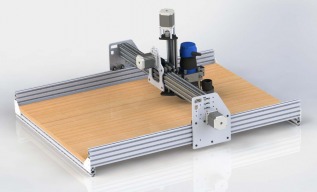

Aluminium OX - Canada

Discussion in 'CNC Mills/Routers' started by sgspenceley, Dec 5, 2014.

Document my OX build process. I will also be sharing SolidWorks parts files & assemblies.

Page 2 of 6

Page 2 of 6