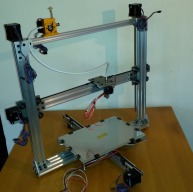

Archer all metal 3D printer

Discussion in '3D printers' started by James Archer, Jun 12, 2016.

Archer - An extendable all metal 3D printer

Discussion in '3D printers' started by James Archer, Jun 12, 2016.

This is an all metal build using OpenBuilds V-Slot linear rails to produce a high quality and cost effective 3D printer. The printer is designed to be scalable for your desired build area and can utilize high quality hotends with 16mm groove mounts such as E3D.