Dogmeat's Custom C-Beam XL

Discussion in 'CNC Mills/Routers' started by dogmeatk, Apr 21, 2017.

Dogmeat's Custom C-Beam XL

Discussion in 'CNC Mills/Routers' started by dogmeatk, Apr 21, 2017.

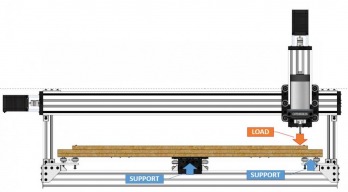

I love the C-Beam XL concept, this build is my custom version with the goal of increasing rigidity for metal milling.