Emmett-Delta

Discussion in '3D printers' started by David Bunch, Jan 8, 2016.

Emmett-Delta

Discussion in '3D printers' started by David Bunch, Jan 8, 2016.

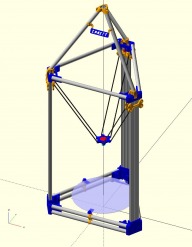

Delta 3d Printer using 3/4" Electrical Metal Tubing (EMT) for Horizontals & 2060 V-Slot for the Verticals and adding a tetrahedron at the top.

Page 2 of 4

Page 2 of 4