Gargantua

Discussion in 'CNC Mills/Routers' started by Spiffcow, Jul 18, 2017.

Plastic Monstrosity

Discussion in 'CNC Mills/Routers' started by Spiffcow, Jul 18, 2017.

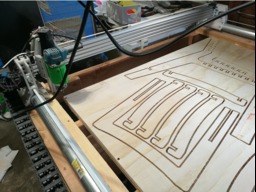

Large inexpensive build that can cut a 4x8 ft sheet with room to spare. Can be built using only a 3D printer and standard parts -- no special CNC'd plates required.

Page 1 of 2

Page 1 of 2