MakerSL MSL-8 OB Vise

Discussion in 'Other Builds' started by Sonny Lowe, Nov 2, 2016.

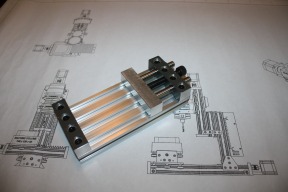

MakerSL MSL-8 OB Vise

Discussion in 'Other Builds' started by Sonny Lowe, Nov 2, 2016.

Small Machining Vise designed around 20x80 Openbuilds Rail System

Page 1 of 2

Page 1 of 2