OpenXY

Discussion in '3D printers' started by Keith Davis, Nov 30, 2015.

OpenXY

Discussion in '3D printers' started by Keith Davis, Nov 30, 2015.

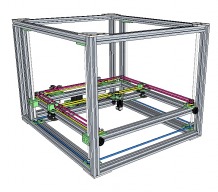

Combines the layout factor of a CoreXY while using Cartesian logic. The design has a fixed build plate - moving an X/Y frame on the Z axis enclosed by an outer main frame.

Page 1 of 2

Page 1 of 2