Project There is No Kill Like Overkill

Discussion in 'CNC Mills/Routers' started by drxlcarfreak, Jun 15, 2017.

Project There is No Kill Like Overkill

Discussion in 'CNC Mills/Routers' started by drxlcarfreak, Jun 15, 2017.

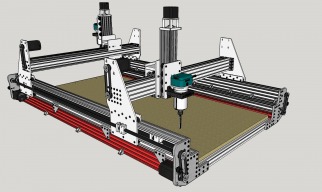

Very stout 2'x4' machine with a deep Z axis