Reference sensor for CNC Tools

Discussion in 'CNC Mills/Routers' started by AK-Creation, Oct 31, 2016.

Reference sensor for CNC Tools

Discussion in 'CNC Mills/Routers' started by AK-Creation, Oct 31, 2016.

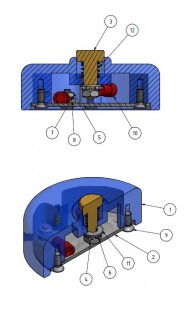

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.