Versabot - All metal 3D printer

Discussion in '3D printers' started by asb_79, Sep 6, 2014.

Versabot - All metal 3D printer

Discussion in '3D printers' started by asb_79, Sep 6, 2014.

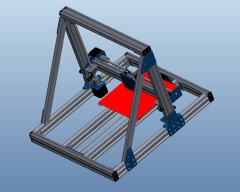

An all metal construction cartesian style 3D printer with a very rigid frame that has the flexibility to function as a desktop milling station or laser cutter with appropriate user designed attachments. Design is scaleable to suit any size requirement. All axis are leadscrew driven. V-Slot and Mini V-wheels have been utilised for the linear rails.