Having built an Ordbot, a Prusa i3 and a Mini Kossel. I find the cartesian style bots much easier to set up and work with. I've had both the Ordbot and Prusa running well but feel the Ordbot could do with a more rigid print platform and the Prusa single plate design is not as rigid as I'd like. The biggest issue I've experienced though, is over time the z-axis motor get out of sync requiring the Gantry to be re-leveled to the bed quite frequently.

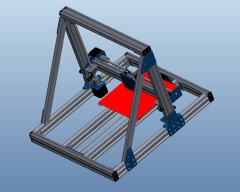

I'm calling this printer the Versabot as it is solid enough to work a a micro milling station with an appropriate spindle attachment. Also, a single motor will be used to drive the z-axis to remedy my leveling issue mentioned above.

The design has been drafted and refined to a point where I'm comfortable to manufacture parts and begin the machine assembly. This machine will be all metal construction for rigidity and the x-axis carriage plate allows for a multitude of attachments to be fitted. In saying this there isn't a reason the parts couldn't be 3D printed.

Detailed build instructions will follow at some stage but hopefully the pictures will be clear enough for the time being. A parts list will follow also.

Leadscrew options are still being evaluated, initially I will use the TR8x8 with anti backlash nuts but I have also been able to source a 10x12 screw to try also.

My inspiration for this build comes from multiple sources, notably the Lautrek, Mendlemax, Prusa i3 and Ordbot but unique enough to warrant it's own build thread.

Update 01OCT14

Apologies for the slow progress, that is a result of having too many Hobbies!

Leadscrews and motors have been installed, 10x12 screws and anti-backlash nuts have been used on the X&Y axis, M8x1.25 has been used for the Z-axis. (I had planned to use 8x8 for the Z, but for a printer it is not worth the added expense).

Here are some images of the z-axis driven by a single motor. If I did this again I'd use stainless threaded rod and Brass nuts. The Brass rod is a bit soft and easily bends.

Versabot - All metal 3D printer

Build in 'Cartesian Style Bots' published by asb_79, Sep 30, 2014.

An all metal construction cartesian style 3D printer with a very rigid frame that has the flexibility to function as a desktop milling station or laser cutter with appropriate user designed attachments. Design is scaleable to suit any size requirement. All axis are leadscrew driven. V-Slot and Mini V-wheels have been utilised for the linear rails.

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

Clint Sweet, Mark Carew, gwandad and 2 others like this. -

-

Build Author asb_79, Find all builds by asb_79

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - CC BY NC

Reason for this Build

Requirement for a compact versatile desktop maker centreInspired by

Lautrek, Prusa i3, Ordbot

![20140919_233941[1].jpg](data/attachments/4/4412-0e36c42c936daa4f3653e699fa1dc7f2.jpg)

![20140919_234001[1].jpg](data/attachments/4/4413-b761726effd5d70cb60be8eb6b69d447.jpg)

![20140919_234016[1].jpg](data/attachments/4/4414-53e906c5a44bd6fa5ed18b62e5b243bf.jpg)