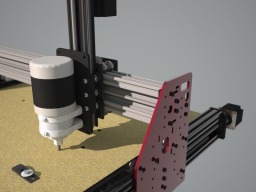

openbuilds rovo c-beam (700*1000)(1000*1000)

Discussion in 'CNC Mills/Routers' started by inhan, Feb 5, 2016.

openbuilds rovo c-beam (700*1000)(1000*1000)한국오픈빌드.

Discussion in 'CNC Mills/Routers' started by inhan, Feb 5, 2016.

Open the build will create open and sharing. 오픈빌드는 만들고 오픈하고 공유합니다.